Deeksha Exports Pvt. Ltd. has world-class infrastructure to meet our customers’ manufacturing requirements, with a production capacity of 70 to 80 tonnes of aluminum alloy per month.

Total Factory Area: 40,000 sq. ft. & built-up: 37,000 sq. ft

Our Infrastructure:

1) Die Casting:

We operate a dedicated and well-equipped High-Pressure Die Casting (HPDC) facility, featuring a range of cold chamber die casting machines from 120 tonnes to 500 tonnes, ideal for producing high-quality aluminum castings for automotive and industrial applications.

🔹 Machine Range & Specifications

Fully Automatic Cold Chamber Die Casting Machines:

-

BMC – 500 Ton – 1 No.

-

Yizumi – 300 Ton – 1 No.

-

BMC – 250 Ton – 1 No.

-

Yizumi – 250 Ton – 2 Nos.

-

Yizumi – 180 Ton – 2 Nos.

Semi-Automatic Cold Chamber Die Casting Machine:

-

HMT – 120 Ton – 1 No.

Our fleet of modern die casting machines ensures consistency, dimensional accuracy, and production flexibility across a wide range of part sizes and volumes.

2) Machining :

We offer total machining solutions with 7 CNC and 11 VMC machines along with conventional drilling, tapping & milling machines for secondary operations.

3) Vacuum Impregnation & Surface Treatment Capabilities

At our facility, we offer advanced solutions to enhance the quality and durability of aluminum and zinc components through Vacuum Impregnation and environment-friendly surface treatments

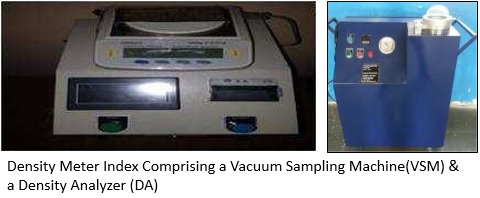

🔹 Vacuum Impregnation (IMP Sealant – 600 mm Capacity)

Our dedicated vacuum impregnation setup features a 600 mm diameter capacity and uses high-quality imported IMP sealants. This process strengthens cast components by sealing internal micro-porosities, making them more robust and suitable for precision applications across automotive, electrical, and industrial sectors.

Key Features:

-

600 mm diameter impregnation capacity

-

Uses premium imported IMP sealants

-

Suitable for aluminum and zinc cast parts

-

Ideal for enhancing structural integrity and performance

🔹 Trivalent Chromium (Cr+3) Surface Treatment

We provide Trivalent Chromium (Cr+3) plating for both aluminum and zinc components, delivering excellent corrosion resistance while meeting global environmental and safety standards (RoHS compliant).

Highlights:

-

Eco-friendly Cr+3 surface coating

-

Excellent corrosion resistance

-

Suitable for a wide range of applications

-

Backed by in-house Salt Spray Testing for performance validation

4)Leak Testing & Ultrasonic Cleaning Capabilities

We ensure the highest standards of component reliability and cleanliness with our precision Leak Testing and advanced Ultrasonic Cleaning facilities.

🔹 Leak Testing

Our facility is equipped to perform accurate leak testing on a wide range of aluminum and zinc components across 2 to 12 bar pressure range. This process ensures that each part meets the required standards for sealing performance and operational safety.

Key Features:

-

Pressure range: 2 to 12 bar

-

Suitable for various geometries and part sizes

-

Ensures assembly readiness for critical applications

-

Supports automotive, hydraulic, and industrial sectors

🔹 Ultrasonic Cleaning

Our ultrasonic cleaning system delivers deep, non-contact cleaning for components by using high-frequency sound waves in a liquid medium. This removes fine contaminants from hard-to-reach areas, ensuring parts are perfectly clean for coating, assembly, or packaging.

Benefits:

-

Removes oils, dust, chips, and machining residues

-

Ideal for precision aluminum and zinc parts

-

Non-abrasive and environmentally safe cleaning

-

Improves coating and plating adhesion

5) Tool Room (In-House) :

Design Capabilities – Die Casting Die Design

Our in-house design office forms the backbone of our toolroom, enabling efficient and precise die casting die design. Staffed with qualified and highly experienced design engineers and CAM programmers, we ensure every tool is developed to meet exacting quality and performance standards.

🔹 Design Software & Tools

We utilize industry-standard CAD and CAM software to create accurate and optimized tool designs:

-

Siemens NX CAD – 1 license

-

Siemens Solid Edge – 1 license

-

Siemens CAM Express – 1 license

🔹 Tool Room Equipment

| Machine | Make | Table Travel / Capacity |

|---|---|---|

| VMC Milling Machine | Haas VF-3 | 1000 mm × 510 mm × 490 mm |

| Spark Erosion (EDM) | Vinpak | 400 mm × 250 mm × 200 mm |

| Radial Drilling Machine | Sidhpura | Ø 30 mm max |

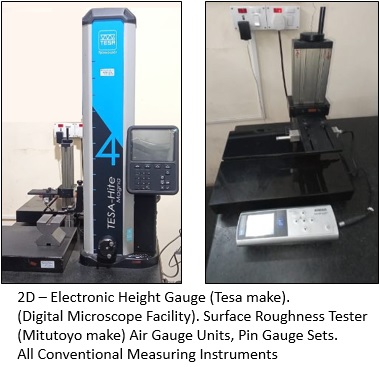

Quality Assurance: Maintaining our Quality System with below equipment:

Stereo Microscope – Stemi 305

Our Quality Assurance laboratory is equipped with a Stereo Microscope (Stemi 305) for precise visual inspection and analysis of components. It provides high-clarity, three-dimensional viewing for detailed examination of surface finish, defects, burrs, and dimensional features. This ensures accurate inspection, enhanced defect detection, and strict adherence to quality standards.

Millipore Testing Machine

Our Quality Assurance laboratory is equipped with a Millipore Testing Machine to ensure the highest level of component and fluid cleanliness. This system accurately measures particulate contamination through controlled filtration and gravimetric analysis, enabling us to meet stringent customer and international quality standards. The facility reflects our strong commitment to precision, reliability, and consistent product quality.

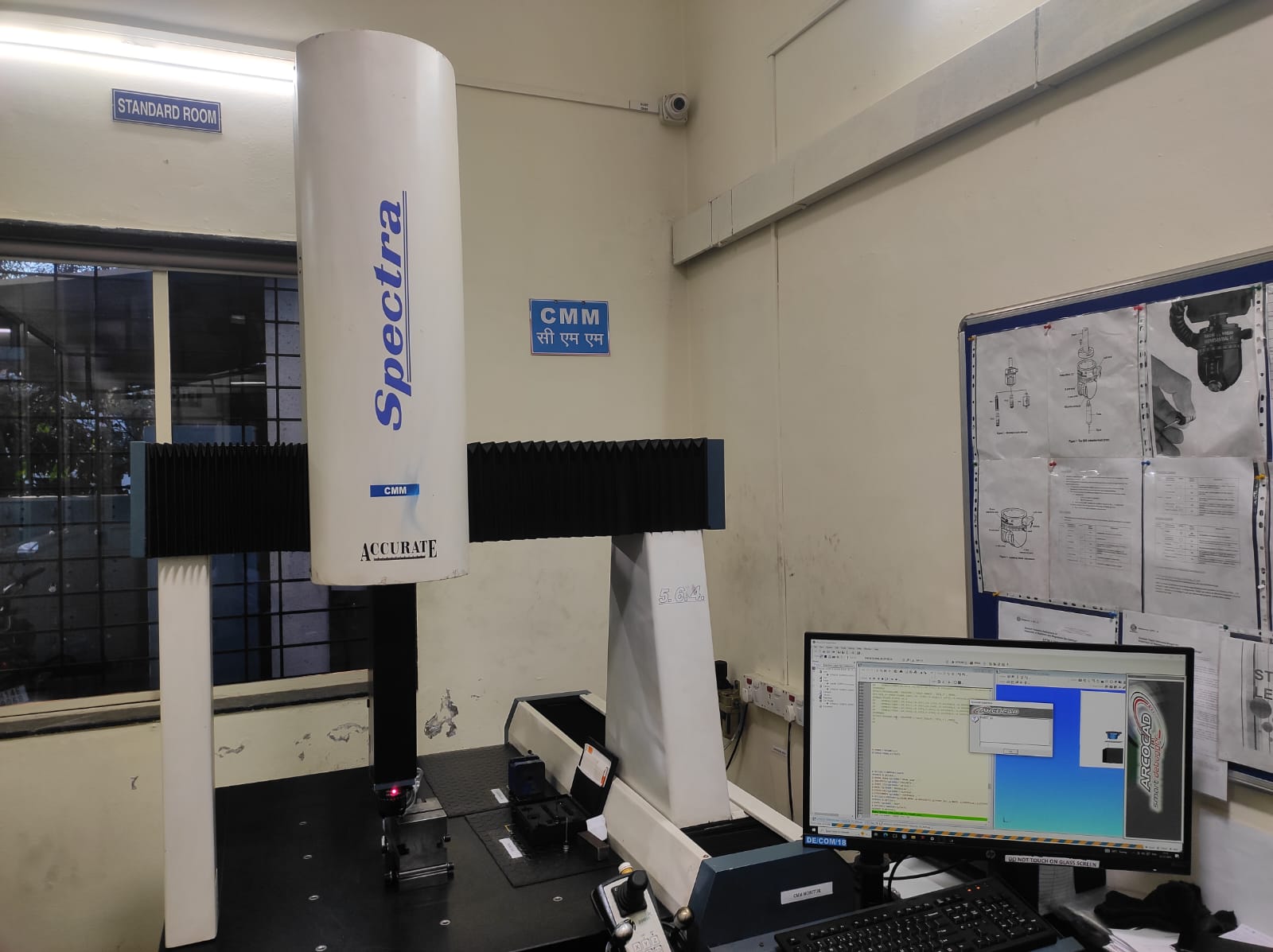

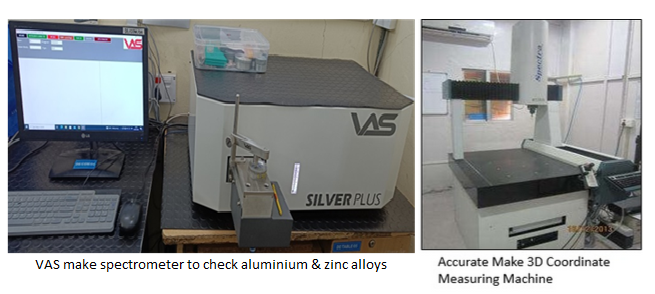

CMM Accurate (Coordinate Measuring Machine)

Our Quality Assurance facility is equipped with a high-precision Coordinate Measuring Machine (CMM Accurate) for accurate dimensional inspection of critical components. The system ensures precise measurement of complex geometries, tight tolerances, and critical features, enabling us to meet stringent customer, ISO, and automotive quality requirements with complete confidence.