Aluminum Die Casting Parts Manufacturer – Deeksha Exports Pvt. Ltd. | India

Welcome to Deeksha Exports Pvt. Ltd., a trusted manufacturer and global supplier of precision aluminum die casting components and turned parts, based in Chakan, Pune, India. Established in 2006, we are an IATF 16949:2016 certified company, serving clients across automotive, electrical, and engineering industries worldwide.

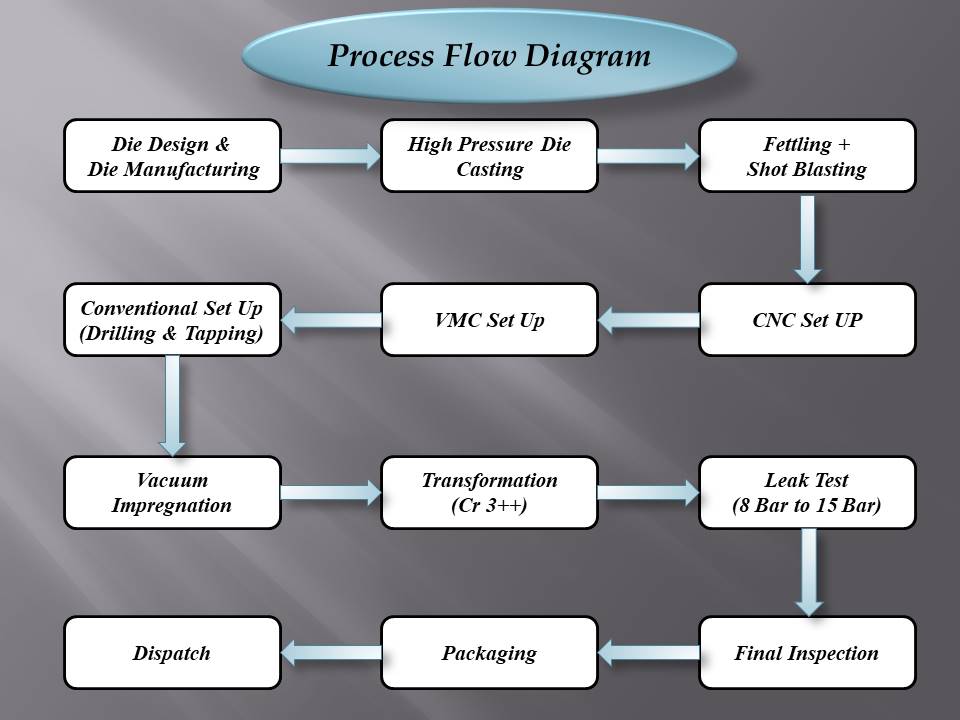

We specialize in high-pressure die casting (HPDC) for aluminum and zinc alloys, with end-to-end capabilities from die design and manufacturing to machined, ready-to-assemble parts.

Why Choose Deeksha Exports for Aluminum Die Casting?

-

Over 20 years of manufacturing excellence

-

IATF 16949:2016 certified – Trusted by global OEMs and Tier-I suppliers

-

Specialized in Aluminum & Zinc HPDC and precision machining

-

Tier-II Approved Supplier for Maruti Suzuki

-

Export-ready supply chain with global shipping capabilities

-

Expertise in Die Design, HPDC, CNC Machining, and Surface Finishing

-

Monthly casting capacity: 70–80 tonnes (Aluminum Alloys)

-

State-of-the-art facility: 40,000 sq. ft. total area | 37,000 sq. ft. built-up

🌟 Our Vision

To become a global leader in aluminum die casting by delivering world-class manufacturing quality, embracing advanced technology, and ensuring minimal environmental impact.

🎯 Our Mission

To be a preferred global supplier of aluminum die casting components and precision engineered parts, while promoting sustainable practices and contributing to a cleaner, greener planet.

Looking for a reliable aluminum die casting manufacturer in India?

📩 Contact us today for RFQs, samples, or technical discussions.

Partner with Deeksha Exports Pvt. Ltd. – Where Precision Meets Performance.

✦ Our Process

📄 Registration Details

📞 Contact Details

📍 Address

Deeksha Exports Pvt. Ltd.

Gat No. 98/1, Ambethan,

Opposite Kalyani Technoforge Ltd,

Waghjai Nagar, Chakan,

Pune – 410501, Maharashtra, India ![]()